PROJECT OVERVIEW

PROJECT DETAILS

- Location Vilnius, Lithuania

Molecular Lightening: Precise Polymer Scission & Viscosity Control via Ultrasound

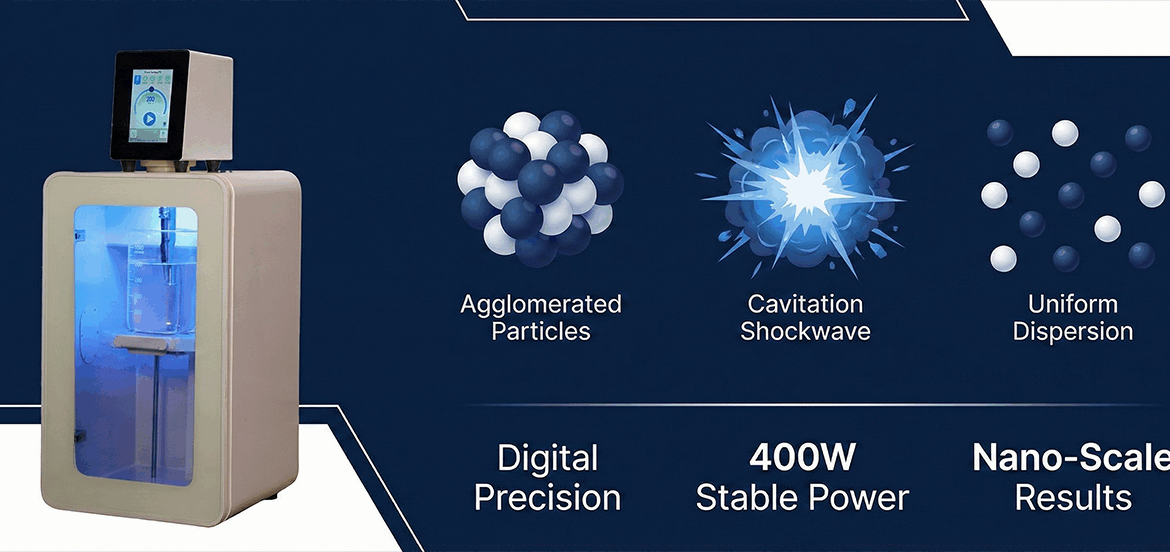

Executive Summary: Molecular lightening (acoustic cracking) utilizes the extreme shear forces of Transient Cavitation to physically snap long-chain polymers. Unlike thermal cracking, the Topsonics 400W digital system ensures exact reproducibility and specific Molecular Weight Distribution (MWD) without extreme bulk temperatures.[Image of ultrasonic probe creating cavitation bubbles in blue liquid]

1. Introduction: The Physics of Ultrasonic Scission

In the realm of material science and chemical engineering, "Molecular Lightening" refers to the controlled reduction of molecular weight (MW) in macromolecules. Unlike thermal cracking, which relies on bulk heating to randomize bond breakage, or chemical digestion which introduces contaminants, ultrasonic processing offers a "cold" mechanical alternative driven by acoustic cavitation.

1.1 From Sound Waves to Molecular Fracture

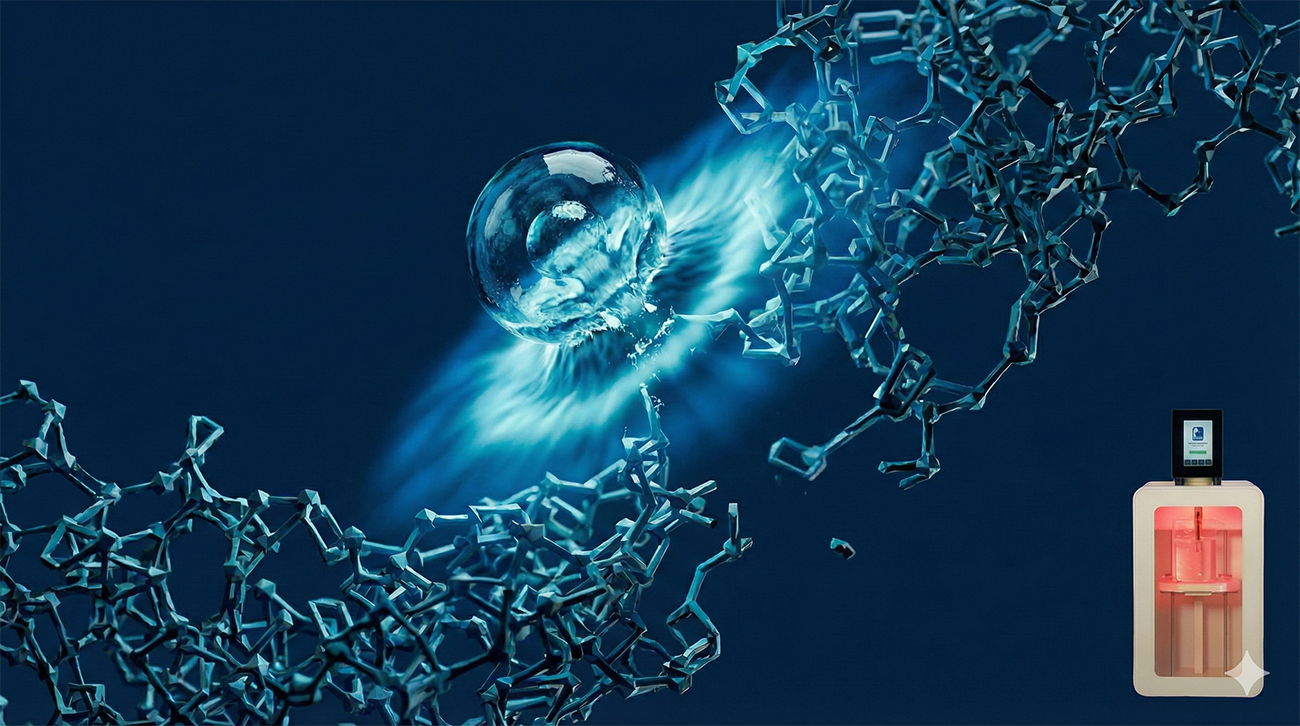

The fundamental mechanism driving this process is the interactions of sound waves with the liquid medium. As high-intensity ultrasound (typically 20 kHz) propagates, it creates alternating cycles of compression and rarefaction. When the local pressure drops below the liquid's vapor pressure, vacuum bubbles form—a phenomenon known as Cavitation.

The efficacy of molecular cracking is determined by the Transient Cavitation regime. During the compression cycle, these bubbles collapse catastrophically. According to Suslick’s Hot Spot Theory, the interior of the collapsing bubble reaches effective temperatures of ~5,000 K and pressures exceeding 1,000 atmospheres.

Critical Mechanism: Shear Force vs. Heat

For molecular lightening of polymers (like Polystyrene, PLA, or Hyaluronic Acid), the primary driver is the Shear Force in the bulk liquid (Zone 3), rather than the thermal plasma inside the bubble (Zone 1). The shockwaves generated by the collapse create extreme velocity gradients. When a long polymer chain is caught in this gradient, the hydrodynamic drag pulls the molecule in opposite directions, causing mid-point scission.

[Image of polymer chain breaking under tension]1.2 Mathematical Modeling of the Collapse

To understand the energy potential available for bond breaking, we must look at the bubble dynamics governed by the Rayleigh-Plesset equation:

This equation illustrates that the bubble wall velocity ($\dot{R}$) and acceleration ($\ddot{R}$) dictate the intensity of the shockwave. In high-viscosity fluids (typical of polymer melts or heavy oils), the Keller-Miksis formulation is more appropriate as it accounts for liquid compressibility and acoustic radiation losses.

2. The Gap: Why Conventional Methods Fail in Rheology

2.1 The "Analog Drifting" Problem

Many laboratories still rely on older, "box-style" ultrasonic processors controlled by analog dials. In molecular lightening, the Polydispersity Index (PDI) is critical. In analog systems, as the viscosity of the sample changes (natural thinning during cracking), the resonance frequency shifts. If the device cannot auto-tune instantly, amplitude drops, resulting in a wide PDI—a mixture of unreacted long chains and over-processed oligomers.

2.2 Thermal Degradation Risks

Traditional thermal cracking requires high energy inputs that often damage chemical functionality. Ultrasonic scission is site-specific; it breaks the backbone while largely preserving functional groups, making it ideal for Gel Permeation Chromatography (GPC) preparation.

3. The Topsonics Solution: Digital Precision for Rheology

At Topsonics, we recognize that reproducibility is the only metric that matters. Our 400W system utilizes a digital frequency tracking algorithm. As viscosity drops, the generator detects impedance changes and adjusts the driving frequency in milliseconds to maintain peak amplitude.

- Smart Tuning: Maintains constant amplitude regardless of viscosity changes.

- Pulsed Operation: Allows heat dissipation (e.g., 5s ON / 5s OFF) to protect sensitive biopolymers like DNA.

3.3 Lab-Scale to Pilot Insights

The data generated by our 400W unit is scalable. By calculating the Specific Energy ($E_s$) in Joules per milliliter, you can model continuous flow systems:

4. Key Applications of Molecular Lightening

- Polymer Analysis (GPC/SEC): Reducing MW to pass through columns without clogging.

- Bio-Refinery: Accelerating the hydrolysis of glycosidic bonds (Cell Disruption).

- Heavy Oil Upgrading: Severing long-chain alkanes and asphaltenes via micro-pyrolysis.

- Hyaluronic Acid (HA): Depolymerizing high-MW HA into specific low-MW grades for cosmetics.

5. Process Comparison Data

The following table contrasts the Topsonics mechanical shear method against traditional thermal and chemical processes.

| Method | Mechanism | Temp. | Selectivity (PDI) | Integrity |

|---|---|---|---|---|

| Thermal Cracking | Kinetic Vibration | >300°C (High) | Poor (Broad) | Oxidation Risk |

| Chemical Hydrolysis | Acid/Base Attack | Variable | Moderate | Salt Residues |

| Topsonics Ultrasound | Mechanical Shear | Ambient | High (Precise) | Preserved |

6. Frequently Asked Questions (FAQ)

Q: Can the Topsonics 400W device crack crude oil for industrial production?

A: No, not for production volume. The 400W unit is a research tool to calculate the specific energy required ($E_s$). Industrial scale requires continuous flow reactors in the kilowatt range.

Q: Does ultrasonic cracking generate free radicals?

A: Yes. Cavitation splits water vapor into $H\bullet$ and $\bullet OH$ radicals. For oxidation-sensitive polymers, we recommend sonication under an inert gas (Argon/Nitrogen).

Q: Why does the liquid get hot if this is a "non-thermal" process?

A: "Non-thermal" refers to the bond-breaking mechanism (shear). However, acoustic energy dissipates as heat. Active cooling is mandatory for molecular lightening.

7. Next Steps for Your Research

If precise control over molecular weight distribution is critical to your work, relying on analog equipment is a variable you cannot afford. Would you like to discuss your specific polymer or fluid matrix with our technical team? We can help calculate the theoretical energy density required for your target viscosity.

- Suslick, K. S. (1990). Sonochemistry. Science.

- Mason, T. J. (1999). Sonochemistry. Oxford University Press.

- Leighton, T. G. (1994). The Acoustic Bubble. Academic Press.