PROJECT OVERVIEW

Ultrasonic Nano-Emulsification

PROJECT DETAILS

- Research Name Nano Emulsification

- Category Process

- Location Vilnius Lithuania

The Physics of Droplet Fracture: Beyond Mechanical Mixing

The creation of a true nano-emulsion—defined often by droplet sizes below 100 nm and optical translucency—is not merely a mixing challenge; it is a physics challenge. Unlike macroscopic mechanical mixing, ultrasonic homogenization utilizes the stochastic and violent power of acoustic cavitation to manipulate matter at a microscopic scale.

Overcoming the Laplace Barrier

The fundamental adversary in emulsification is Laplace Pressure. The pressure required to deform and break a droplet is inversely proportional to its radius ($R$):

$$ \Delta P = \frac{2\gamma}{R} $$Where $\gamma$ is the interfacial tension. As the droplet size decreases, the internal pressure increases exponentially, requiring exponentially more energy to fracture it further.

Conventional rotor-stator mixers generate shear forces but often fail to overcome this barrier for droplets under 300 nm. In contrast, ultrasonic cavitation generates "hot spots." When a cavitation bubble collapses, it releases energy densities impossible to achieve under ambient conditions, driving the droplet size down well into the nano-range.

Note on Chemical Interactions

While the physical shear forces drive emulsification, the high-energy environment also facilitates chemical reactivity. For a deeper analysis of how these forces influence chemical synthesis, refer to our detailed guide on Sonochemistry.

The Technology Gap: Why "Analog" Fails at the Nano-Scale

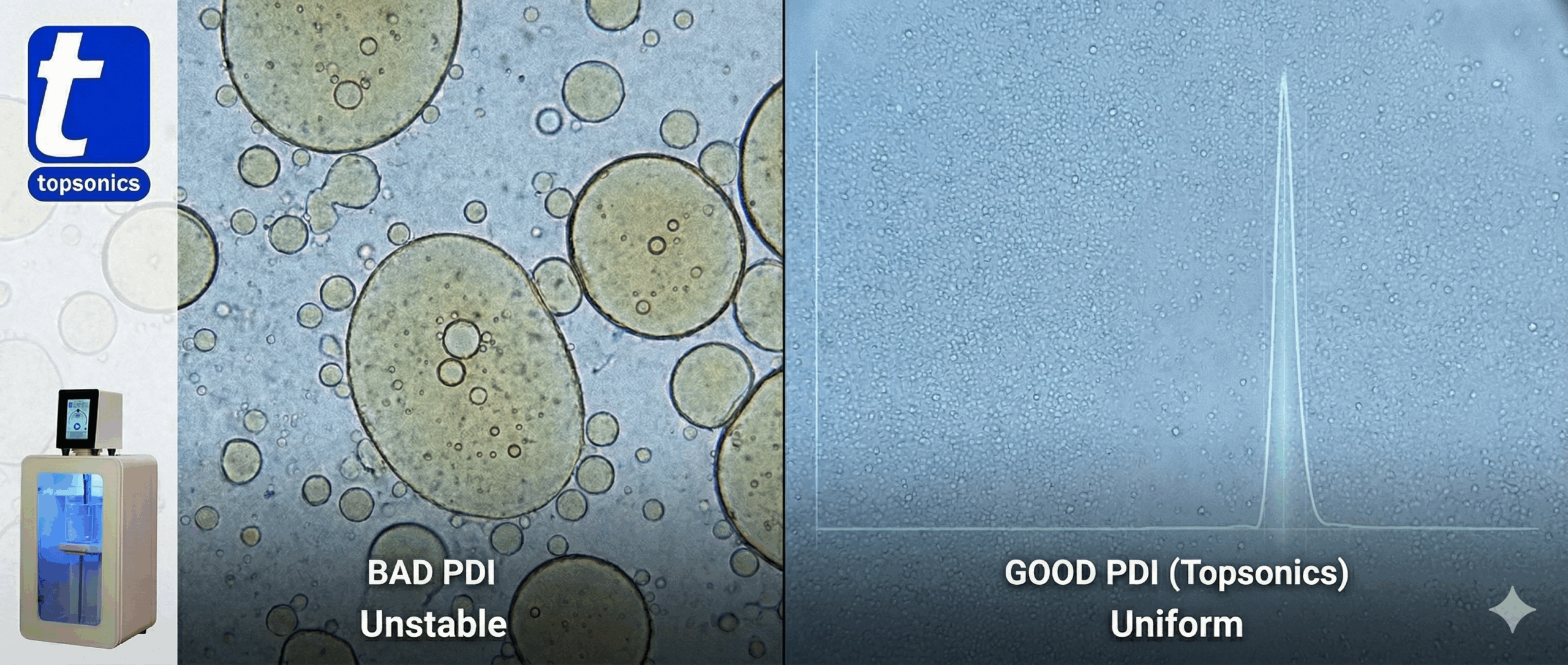

In the pursuit of pharmaceutical-grade stability (PDI < 0.2), the consistency of the acoustic field is paramount. This is where many laboratories struggle when using older, analog ultrasonic equipment.

The Frequency Drift Trap

As ultrasound propagates through a liquid, it generates heat. As the temperature of your emulsion rises, the speed of sound ($c$) within the medium changes. Since acoustic impedance ($Z$) is defined as $Z = \rho \cdot c$, the optimal resonance frequency of the system shifts.

- The Analog Failure: Old-school homogenizers with manual tuning knobs cannot react to these millisecond-scale changes. The system falls out of resonance, amplitude drops, and the "shear" becomes inconsistent.

- The Consequence: You end up with a mixture of over-processed and under-processed droplets. This high Polydispersity Index (>0.3) drives Ostwald Ripening, where large droplets grow at the expense of small ones, causing the emulsion to separate days or weeks later.

The Topsonics Advantage: Digital Precision on the Benchtop

At Topsonics, we have engineered our 400W system to eliminate the variables that cause batch-to-batch inconsistency. We don't just supply power; we manage the physics.

Smart Tuning & Reproducibility

Our system employs active digital feedback. It continuously monitors the acoustic impedance of your sample—whether it's a viscous cannabis oil or a light aqueous buffer—and micro-adjusts the frequency to maintain peak amplitude.

User-Centric Design

The modern 5-inch touch interface allows you to set precise energy limits (Joules) or time. This removes the "human error" of dialing in knobs, ensuring that the experiment you run today is identical to the one you run next month.

Sample Protection

High-intensity cavitation generates heat. Our sleek, modern sound enclosure and stand design allow for easy integration of ice baths or jacketed beakers, critical for preserving heat-sensitive compounds like cannabinoids or proteins.

"In nano-emulsification, 'power' is useless without 'control.' A 400W system that holds resonance is vastly superior to a 1000W system that drifts."

topsonics scientific editor

Formulation Science: Surfactants and Ratios

Even the best hardware requires correct chemistry. The formation of a stable interfacial shell is critical to prevent coalescence.

Matching the HLB

For hydrophobic cores (like cannabis oil or Vitamin E), selecting the right surfactant blend to match the Hydrophilic-Lipophilic Balance (HLB) is essential.

- Lipophilic Surfactants: Such as Span 80 (HLB 4.3), stabilize the oil phase.

- Hydrophilic Surfactants: Such as Tween 80 (HLB 15.0), stabilize the water interface.

A common mistake is using a single surfactant. A blend often provides better packing at the interface, reducing tension ($\gamma$) and lowering the energy required ($ \Delta P$) to break the droplets.

Comparative Analysis: Emulsification Methods

The following data highlights why Ultrasound is the preferred method for lab-scale nano-emulsions compared to traditional methods.

| Method | Typical Droplet Size | PDI (Uniformity) | Cleaning Time |

|---|---|---|---|

| Rotor-Stator Mixer |

2 µm - 10 µm

|

High (Broad) | Fast |

| High Pressure Homogenizer |

< 100 nm

|

Low (Excellent) | Slow (Complex valves) |

| Topsonics 400W (Ultrasonic) |

20 nm - 100 nm

|

Low (< 0.2) | Instant (Wipe probe) |

Frequently Asked Questions (FAQ)

Q1: How do I prevent my emulsion from overheating during sonication?

Heat is a byproduct of cavitation. We recommend using a pulsed mode (e.g., 5 seconds ON, 5 seconds OFF) which is easily programmable on the Topsonics touch screen. Additionally, always immerse the sample beaker in an ice bath.

Q2: Can I scale up the results from the Topsonics 400W to industrial production?

Yes. The mechanism of acoustic cavitation is scalable. However, scale-up requires moving from batch processing to continuous flow cells to ensure every microliter receives the same Specific Energy ($J/mL$). The 400W unit is ideal for determining the precise energy density required before scaling.

Q3: Why is my emulsion cloudy instead of translucent?

Cloudiness usually indicates droplets >100 nm. This could be due to insufficient energy input (increase time or amplitude) or an incorrect surfactant HLB ratio. Ensure your specific energy input is sufficient to overcome the Laplace pressure.